Where and how to store polyethylene pipes

Ara Sepahan Pipe Water Storage

Ara Sepahan water pipe warehouse: The movement of all types of polyethylene pipes must be fully controlled and pulling on pipes, fittings, and manholes must be strictly avoided. Polyethylene pipes become slippery in cold, wet weather. It is not recommended to move these pipes in weather conditions and temperatures below -20. Avoid dropping pipes and fittings. Pulling/lifting points must be completely free. Use special and suitable devices for this purpose.

The means of transporting polyethylene pipes must be free of sharp objects and completely flat and clean. When packaging, the main points must be strictly observed to prevent the pipes from slipping or moving on top of each other. Secure the pipes in a way that they do not move or get damaged due to excessive pressure, and prevent products from being contaminated with oil, petroleum products, or similar substances. Unloading products using belts and wedges will increase safety.

When maintaining and storing polyethylene pipes, due to their nature, certain points must be observed, and observing these points will increase the useful life of polyethylene pipes.

Pipe storage area

- The best place to store polyethylene pipes is indoors to reduce the harmful effects of sunlight’s UV rays on polyethylene pipes.

- If the pipes are to be stored outdoors for a maximum of one month or less, it is necessary to place a suitable covering (such as a tarpaulin) on the pipes. Otherwise, it should be stored under a roofed space.

- The pipe storage area must be flat, have sufficient space to accommodate transport trucks, handling equipment, and load handling, as well as a suitable place for temporary cargo storage.

- The storage location must be such as to protect the pipes from physical damage.

- General requirements include things like having enough space, having a level and relatively smooth surface, free of rocks, debris, or other materials that may damage pipes and components or interfere with the moving process.

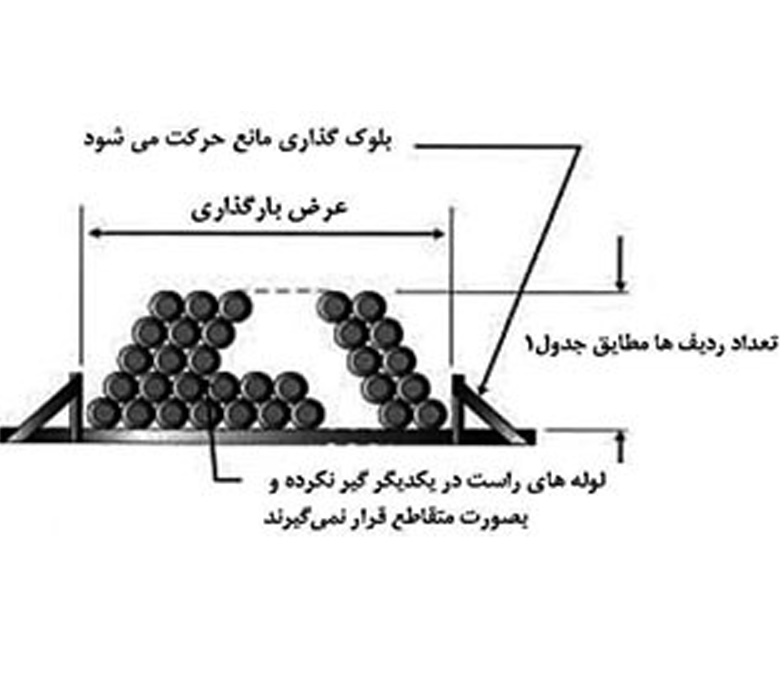

Height of polyethylene pipes in the warehouse

If the storage area is flat and level, the polyethylene coiled pipes can be stacked on top of each other to a total height of about 1.5 meters. Limit the overlap height to about one meter for surfaces that are not perfectly level.

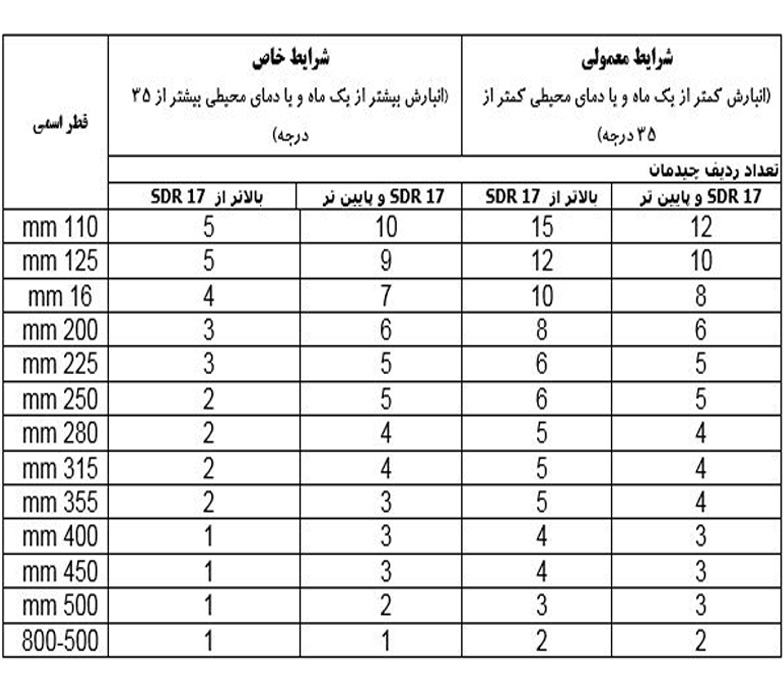

Depending on the environmental conditions and the length of time the pipes have been stored, the arrangement will vary:

General issues and safety tips for maintaining polyethylene pipes

- Black polyethylene pipes contain soot, so they absorb light and retain heat. This causes the pipe to heat up and expand, so it is necessary to exercise caution when moving it to prevent breakage, bending, or permanent deformation. If possible, moving hot pipes that have been exposed to sunlight for a long time should be avoided.

- In cold temperature conditions (below zero degrees Celsius), care must be taken to avoid damaging the pipes. In these conditions, there is a possibility of breakage for polyethylene pipes. In very cold temperatures (less than 20 degrees), moving pipes should be avoided if possible.

- When unloading pipes from the machine, avoid dropping the pipes on the ground.

- When moving pipes with a forklift, the fork of the forklift should be as flat as possible to prevent damage to the inner wall of the pipe.

- Avoid applying excessive pressure to the beginning of the pipe with the forklift fork during transportation and only use the forklift fork to lift the pipes.

- The storage area for pipes must be flat, level, free of stones, and free of any chemicals harmful to the pipes.

- Avoid pulling pipes on the ground.

- Be sure to wear work shoes when carrying heavy objects.

- When moving a load with a forklift, avoid standing next to it if possible.

- Polyethylene is flammable, so avoid lighting a fire near it.